In an era where precision and efficiency are paramount, custom CNC milling services emerge as a cornerstone of modern manufacturing. These services offer a tailored approach, allowing businesses to create intricate designs and components that meet specific requirements, ultimately streamlining production processes.

Imagine a world where every part is crafted with unparalleled accuracy and consistency, reducing waste and turnaround time. With advanced technology and skilled operators, custom CNC milling is not just about cutting materials; it’s about revolutionizing the way products are conceived and constructed.

As manufacturers strive for excellence, understanding how these services can enhance workflows becomes essential. Join us as we explore the transformative benefits of integrating custom CNC milling into your manufacturing arsenal.

Introduction to Custom CNC Milling Services

Custom CNC milling services represent a pivotal advancement in modern manufacturing, transforming the way businesses approach precision machining. Imagine a process that tailors every cut to your exact specifications, enhancing both speed and accuracy while reducing waste.

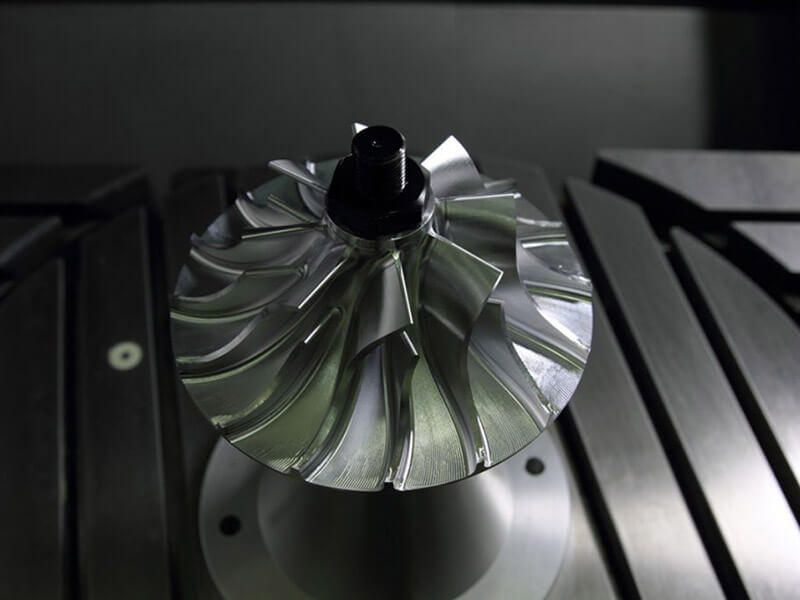

From intricate prototypes to large-scale production runs, custom cnc milling can adapt to the specific needs of your project, regardless of its complexity. This flexibility not only allows for innovative designs but also ensures consistency and superior quality across the board.

As industries evolve, the demand for bespoke solutions grows, making custom CNC milling not just an option, but an invaluable asset in todays competitive landscape. Embracing this technology can lead to remarkable improvements in efficiency, cost-effectiveness, and product excellence.

Benefits of Custom CNC Milling in Manufacturing

Custom CNC milling serves as a transformative force in the manufacturing realm, offering a plethora of advantages that can significantly streamline production processes. By enabling the fabrication of intricate, precise components tailored to specific design requirements, manufacturers can achieve a level of customization previously deemed unattainable.

This tailoring of parts not only enhances functionality but also optimizes material usage, ultimately. Moreover, the efficiency of CNC milling means faster turnaround times; what once took weeks can often be accomplished in days.

As production demands fluctuate, this adaptability allows manufacturers to pivot quickly, meeting urgent needs without compromising quality. In a fiercely competitive landscape, the ability to produce complex geometries with consistent accuracy is not just a benefit; it’s a necessity for staying ahead.

Thus, embracing custom CNC milling can elevate operational capabilities, turning manufacturing challenges into avenues for innovation and growth.

Key Considerations for Optimizing Your CNC Milling Process

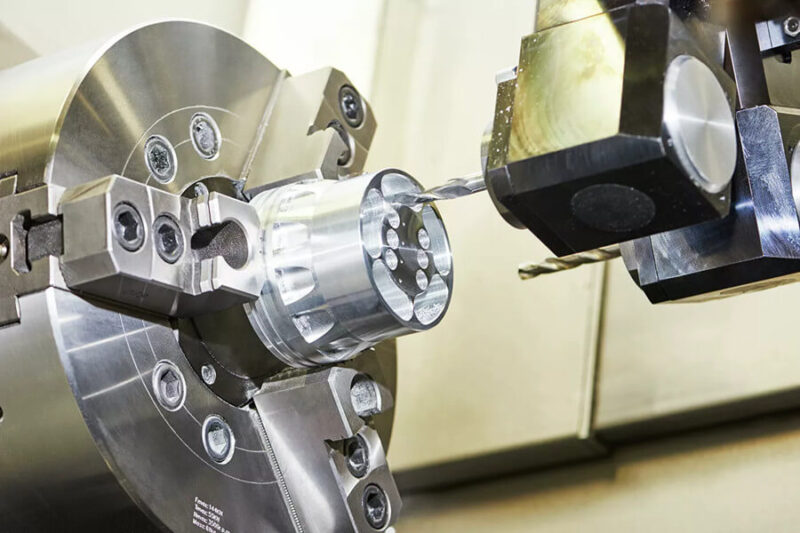

When optimizing your CNC milling process, several key considerations come into play that can dramatically enhance efficiency and precision. First, selecting the right tooling is paramount; consider the materials you’ll be working with and the specific tolerances required for your project.

Additionally, the configuration of your machine settings—such as feed rates and spindle speed—can significantly impact both the quality of the finished product and the time taken for production. Equally important is the role of advanced software solutions that can aid in design simulations and machining strategies; they not only streamline operations but also minimize errors.

Remember, regular maintenance of your CNC equipment cannot be overlooked—keeping machinery in optimal condition ensures consistent performance. Lastly, invest in skilled operators who understand the intricacies of the process; their expertise can make all the difference in achieving the desired outcome while navigating the complexities of CNC milling.

Conclusion

In conclusion, integrating custom CNC milling services into your manufacturing process can significantly enhance efficiency, precision, and flexibility. By leveraging advanced technology and tailored solutions, businesses can optimize their production capabilities, reduce waste, and achieve higher quality outcomes.

The adaptability of custom CNC milling allows manufacturers to meet diverse demands and address specific challenges, ultimately leading to a more streamlined operation. As industries continue to evolve, embracing these specialized services will be crucial for staying competitive and driving innovation in manufacturing.